I.Failure description:

Some users in the market report that it is difficult to start after the replacement of the diesel filter element. The reason is that air enters the fuel system during the replacement process. This TQ introduces the method of exhausting the fuel system after replacing the filter element and the corresponding method when exhausting is difficult.

II.Status description:

1.Brief introduction of fuel transfer pump:

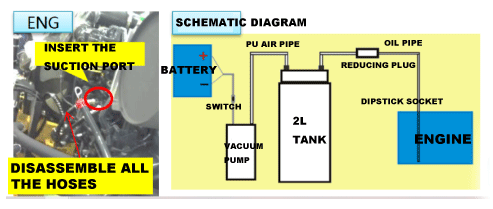

In response to national fuel emission requirements, the -8M0 model has been improved on fuel exhaust: the fuel delivery pump (automatic) has replaced the transmission hand oil pump (manual)

2.Start-up and exhaust steps of fuel delivery pump:

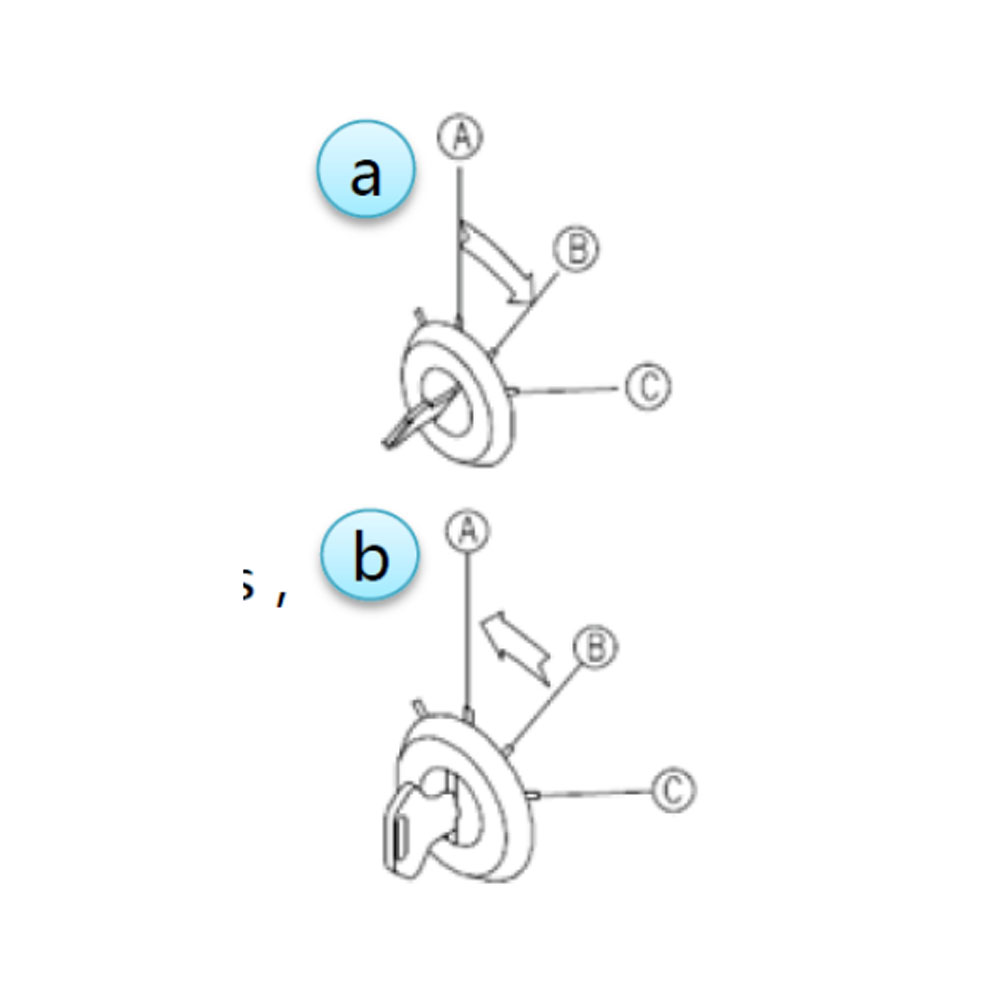

①As shown in Figure a, insert the start switch key and turn the key to the ON position (B) to start the fuel delivery pump;

②As shown in figure b, keep the key in the ON position (B) for 30 seconds, then turn it to the OFF position (A) and wait for 10 seconds;

③ Repeat steps ① and ② four times, if it is crude oil, repeat steps 1 and 2 five times;

④Turn the start key to the START position to start the engine. Do not continuously rotate the motor for more than 20 seconds. If the engine does not start, wait at least 2 minutes before starting. This operation can be repeated up to 4 times;

3. Effects, limitations and corresponding methods of fuel delivery pump:

Effect: Fuel filter element replacement cycle: 500h→1000h, the filtration accuracy of fuel filter element of -8 model is improved;

Limitations: In case of low-quality fuel, it is difficult to exhaust gas after 4 exhaust operations;

Corresponding method: It is recommended to purchase (JD, Tmall, etc.) and install a vacuum pump to improve the exhaust effect;

III. Installation method of vacuum pump:

1. Operation before installation:

① Put down the working device and turn off the engine;

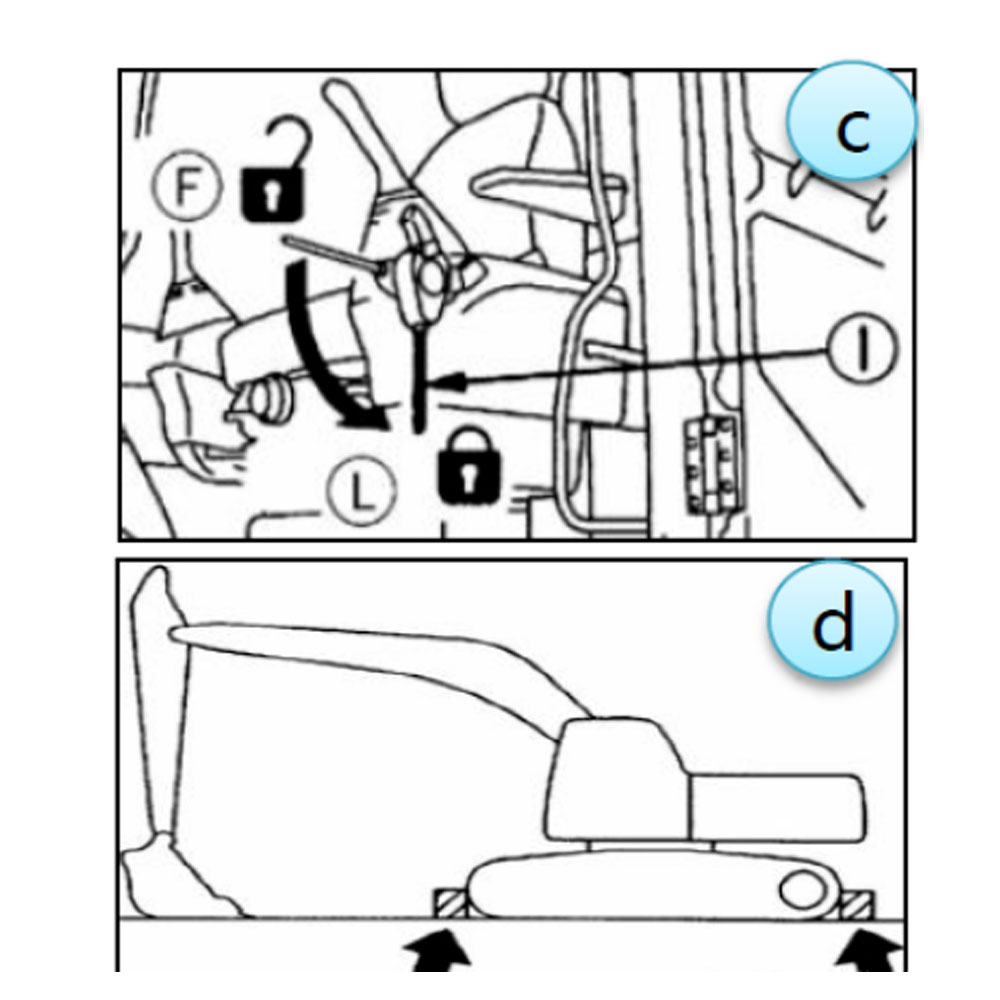

②As shown in Figure c, turn the start switch to the "ON" position, operate the joystick of the working device at full stroke forward, backward, left and right 2 to 3 times to eliminate the residual pressure in the hydraulic system, and then move the safety lock lever (1) To the locked position (L);

③Check that the battery relay is off and the main power supply is not connected;

④ As shown in Figure d, put a block under the crawler to prevent the machine from moving;

2. Installation method:

Parts preparation: oil storage tank, vacuum pump, gas pipe, oil pipe