I. Overview

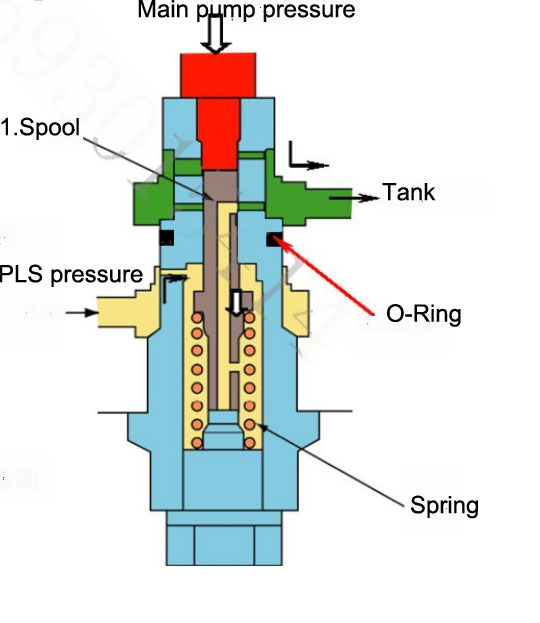

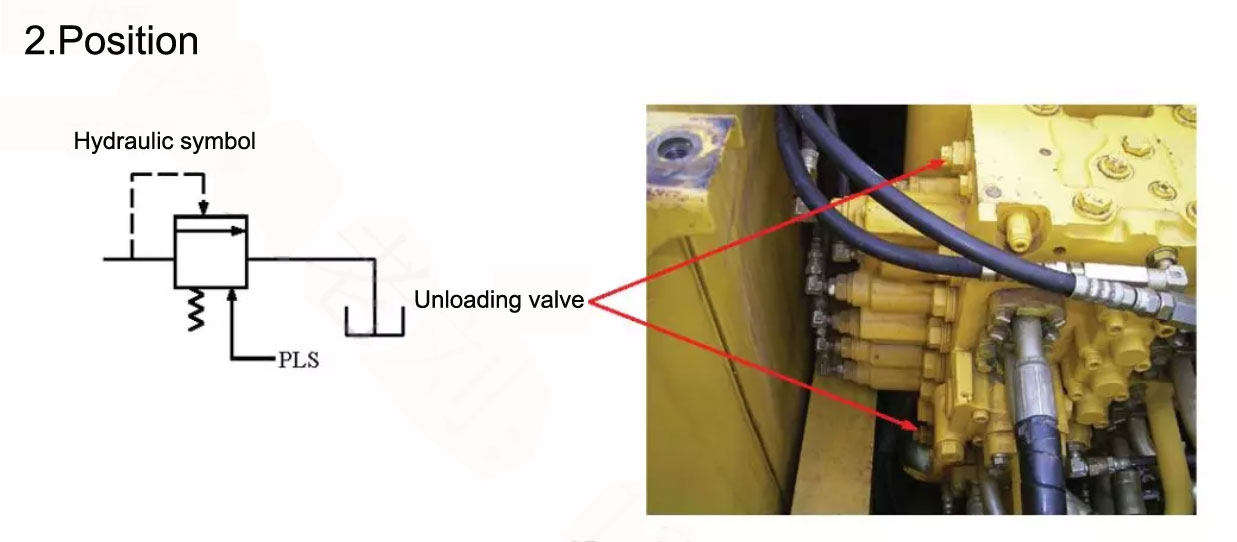

Unloading valves are installed on the upper and lower ends of the main control valve, one piece on the top and the other on the opposite side of the main relief valve. The maximum pressure of the entire hydraulic system is set by this valve when all operating levers are in a neutral position. At this time, the oil pumped by the main pump returns to the fuel tank through the unloading valve. In normal operation, the valve is always closed (unloading valve setting pressure 40kg / cm2).

4. Working principle

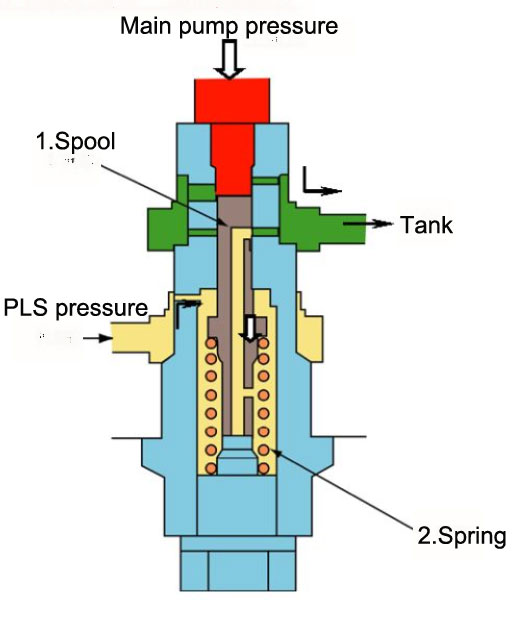

1 When all operating handles are in the neutral position (at this time PLS pressure = 0kg / cm2)

① Pump pressure gradually rises to 40kg / cm2

② The spool (1) is pushed down against the force of the spring (2)

③Pressure oil flows back to the fuel tank

④ Main pump pressure drops

⑤ When the main pump pressure drops below 40kg / cm, the spring (2) pushes the valve core (1) back to close the passage between the main pump oil and the fuel tank

⑥ When the main pump pressure rises more than 40kg / cm again, repeat steps (2) 3) 4) 5)

Main pump pressure is stable at 40kg / cm2

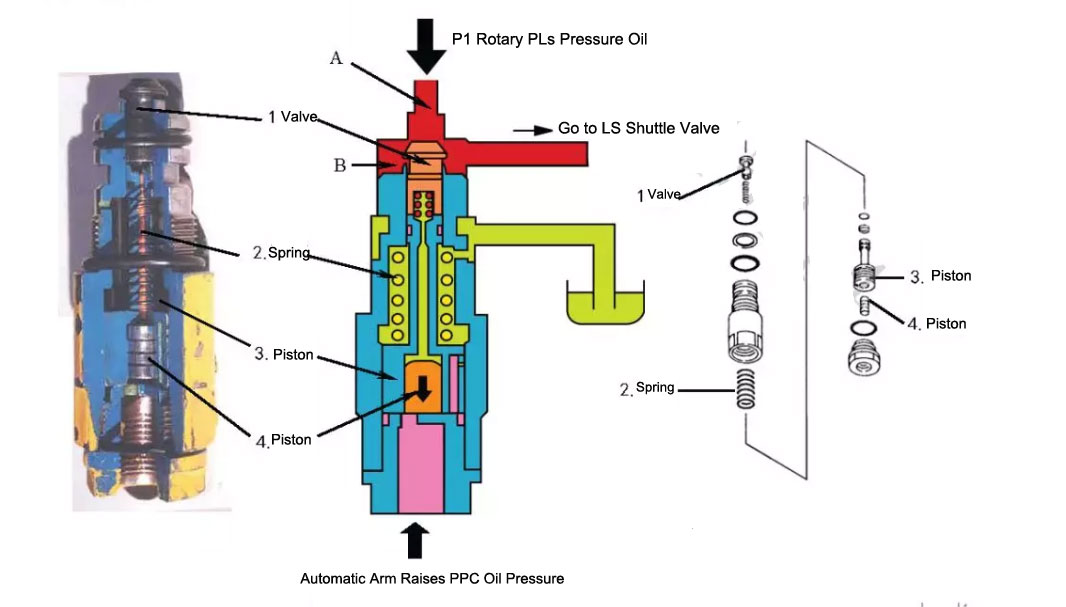

2 at work (at this time the PLS pressure is slightly less than the main pump pressure)

① Main pump pressure rises

↓

② PLS pressure also rises simultaneously

↓

3) The downward thrust generated by the main pump pressure is less than that generated by the PLS pressure

Sum of thrust + spring (2)

↓

④ The spool (1) cannot be pushed down (that is, the unloading valve is in normal operation

(Closed all the time)

↓

⑤Main pump pressure is maintained

5. Fault diagnosis

Failure phenomenon: the pressure of the main pump is lower than the specified value (355kg / cm2)

Inspection result: 0 rings (3) is damaged

Failure analysis: PLS pressure directly flows back to the fuel tank through the damaged O-ring, and the main pump pressure on the spool (1) cannot be supported by the spring force only, causing the spool (1) to open downwards in advance, and the main pump pressure passes through the fuel tank As a result, the main pump pressure drops and the system pressure is insufficient.

Troubleshooting: Replace with new O-ring.