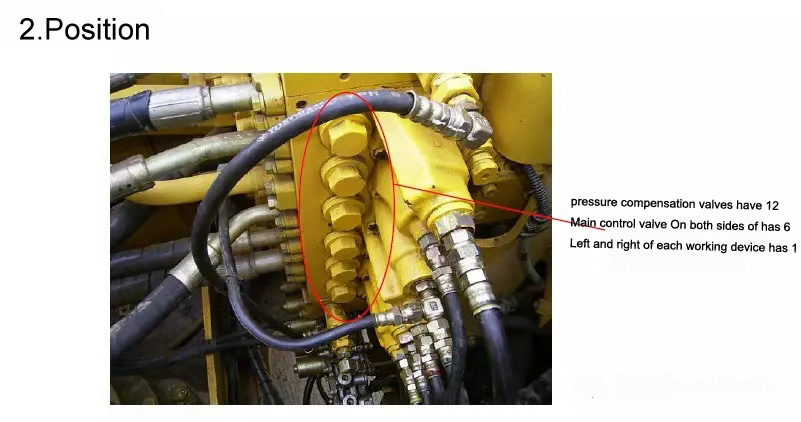

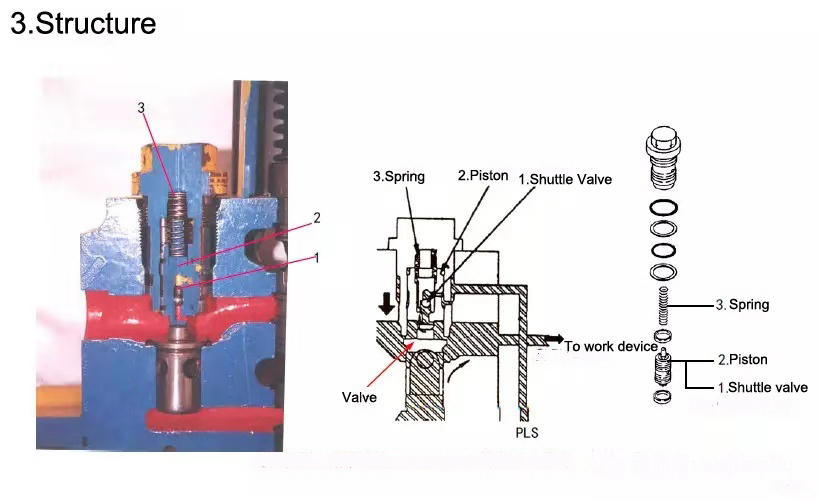

Pressure compensation valve

1. Overview

In the OLSS system, there is no pressure compensation valve. When the two actuators move at the same time, the operating handle needs to be adjusted from time to time to adapt to the changing load of the actuator to ensure the coordination of the actions of the two actuators. In the CLSS system, because of the pressure compensation valve, regardless of the constantly changing actuator load, only the relative stroke of the two operating handles can be set to ensure the coordination of the two actuators when they are acting simultaneously.

4.working principle

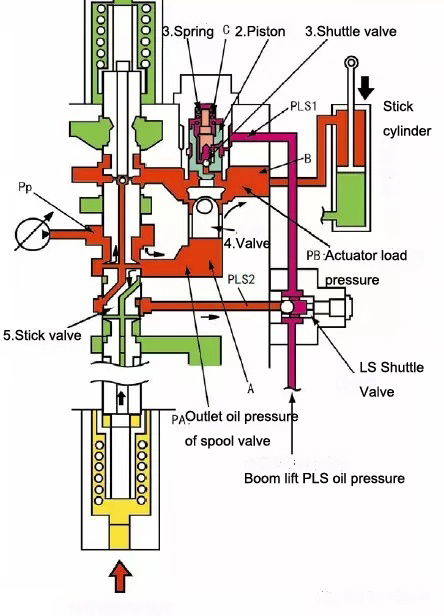

1) For example, when the boom is lifted and the stick is unloaded simultaneously

The load PB1 of the boom is greater than the load PB2 of the stick.

The PLS1 generated by the boom is larger than the PLS2 generated by the stick, and as the system PLS, enters the LS circuit of the system.

The load B of the stick cylinder is less than the load of the boom oil. If there is no pressure compensation valve, the speed of the stick cylinder will be much faster than that of the boom cylinder.

At this time, the boom lift PLS1 pushes down the shuttle valve (1) in the stick pressure compensation, and the PLS oil pressure enters the spring (3) chamber C through the passage in the piston (2).

The piston (2) and valve (4) are pushed down by PLS1 oil pressure.

Because the valve (4) is down, the oil flowing from A to B is throttled, and the oil pressure at A (the stick slider valve outlet oil pressure) rises until it is equal to the boom spool valve oil pressure.

Because the pump pressure PP (the oil pressure at the stick/boom slide valve inlet) is the same, and the oil pressure at the outlet of the stick and boom slide valve is equal at this time (that is, the pressure difference between the inlet and outlet of the stick and boom slide valve is equal) ), So the oil flow to the arm and boom cylinder is only distributed in proportion to the opening area of each spool valve.

When two actuators move at the same time, you only need to control the size of the opening area of each main spool valve to ensure the coordination of the two actuators.

2) The load of the actuator is the highest load when it is operated alone or in combination.

This actuator pressure compensation valve only functions as a check valve.

For example, when the load at B suddenly rises and is higher than the system LS pressure, PB pushes the shuttle valve (1) upward, and PB enters the spring (3) chamber C through the passage in the piston (2), and the piston (2) and the valve (4) move in the closing direction to prevent abnormal high-pressure backflow and prevent the main oil circuit from being affected by this pressure.