The "legs and feet" of the excavator are not agile. It turns out that there are problems in these places.

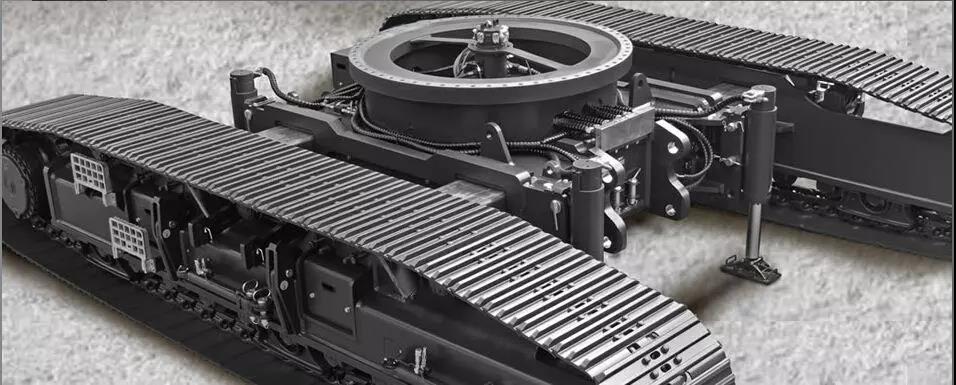

The excavator track is certainly not unfamiliar to the majority of friends. If the mechanical arm of the excavator is the arm of the excavator, the track (four rollers and one track chain) is the leg of the excavator. If the track is out of order, the leg of the excavator will be not agile. If the track cannot be properly maintained, various problems will arise, such as oil leakage from the track roller, broken carrier roller, inconsistent tightness of the track chain, and other problems of the excavator. It is a problem related to the four rollers and one track chain. The four rollers and one track chain are directly related to the working performance and walking performance of the excavator.

Today I will introduce the maintenance methods of the four rollers and one track chain.

First: Track roller maintenance

During work, try to avoid the track rollers being soaked in mud for a long time. After the work is completed every day, the unilateral track should be propped up, and the walking motor should be driven to throw away dirt, debris, and other debris on the crawler.

Although it is not wintering yet, it is also beneficial to know in advance. In winter, the seal between the track roller and the shaft is most afraid of icing and scratching, which will cause oil leakage, so pay special attention in this regard. Damage to the roller can cause a lot of failures, such as walking deviation, walking weakness and so on.

Second: the use of Idler

The idler is located in front of the X-frame, and it is composed of an idler and a tension spring installed inside the X-frame.

During the use of the guide wheel, everyone will have wrong operating habits or brute force operation. Keep the guide wheels in front during work and walking, this can prevent abnormal wear of the rails, the tension spring can also absorb the impact of the road during work and reduce wear.

Third: use of sprocket

The sprocket is located at the rear of the X-frame because it is directly fixed on the X-frame and has no shock absorption function. If the sprocket is walking forward, it will not only cause abnormal wear to the sprocket ring and track chain but also have an adverse effect on the X-frame, which may cause early cracking and other problems.

The shield plate of the travel motor can protect the motor. At the same time, the internal space will also enter some dirt and gravel. This will wear away the oil pipes of the travel motor. The water in the soil will corrode the joints of the oil pipes. so the shield plate should be opened regularly to clean the dirt inside.

Fourth: Use of the carrier roller

The carrier roller is located above the X-frame, and its role is to maintain the linear motion of the track chain. Just as the carrier roller is damaged, the track chain cannot keep straight. The most basic maintenance of the carrier roller is to prevent oil leakage. Basically, you can only replace the oil leakage of the carrier roller with a new one, but the price of a carrier roller is not cheap, so pay more attention to the cleanliness of the X-frame of the excavator, and clean up the dirt and sand in time. The service life of the carrier roller is effectively increased!

Fifth: Use of the track chain

The track chain is mainly composed of track plate and chain links, and the track plate is divided into standard plate and extension plate. Standard plates are used for earthwork conditions, and extension plates are used for wetland conditions.

When walking, the broken stones sometimes gets stuck in the gap between the two plates. When turning to contact with the ground, the two plates will be squeezed, and the track plate will be prone to bending and deformation. Prolonged walking can also cause cracks in the track plate bolts.

The chain link is in contact with the sprocket ring and is driven to rotate by the sprocket ring. Overtightening the track chain can cause early wear of the chain links, sprocket ring, and idler. Therefore, depending on the construction road conditions, it is necessary to adjust the track chain tension.

Summary

In fact, the undercarriage parts are an indispensable part of the whole excavator, and they are also the parts that require more attention from friends. Good operating habits and correct maintenance methods can save more maintenance costs!