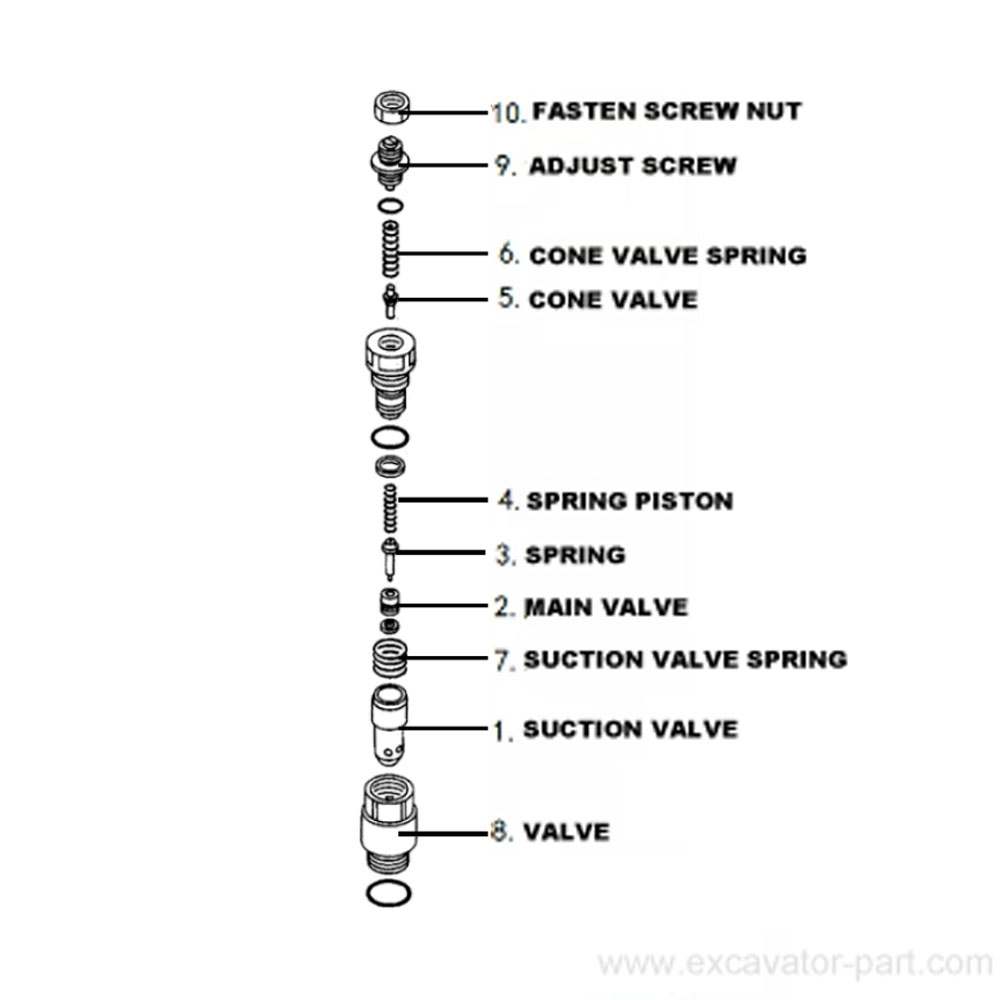

I. What is the safety valve?

The safety suction valve is installed on each branch of the hydraulic device (cylinder, motor). It has the following two functions (take the oil cylinder as an example):

1. When the working device is subjected to abnormal impact from the outside, abnormally high pressure will be generated in the oil cylinder, and the safety suction valve will be opened to discharge the abnormally high pressure back to the fuel tank. In this case, the valve functions as a safety valve to protect the related hydraulic cylinders and hydraulic tubing.

2. When negative pressure is generated in the oil cylinder, the valve acts as an oil suction valve, replenishing oil from the tank pipeline to the negative pressure zone to avoid the formation of vacuum and cavitation.

Note: Failure problems, such as low safety valve setting pressure or parts wear and leakage, will cause the corresponding actions to be weak. For example, the big arm falls off, the walking deviation, etc.

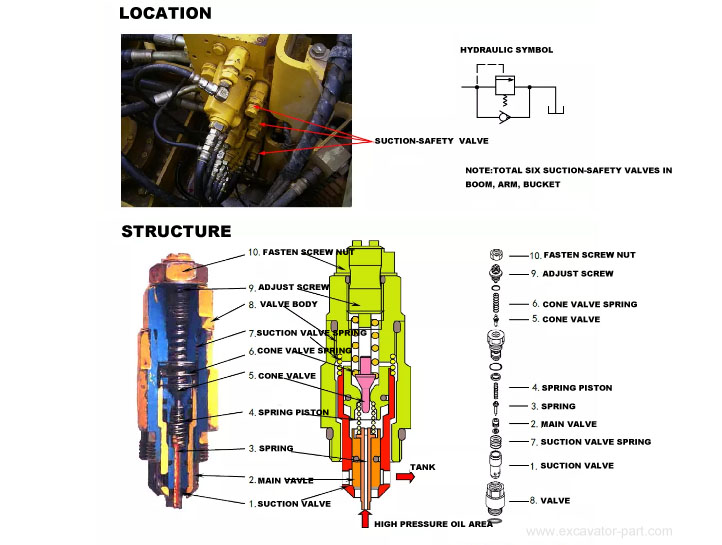

II.Location

III.Working principle

Safety effect:

①The oil pressure in the high-pressure oil zone rises to 390kg/cm2

↓

②The high-pressure oil pushes the poppet valve (5) to overcome the force of the spring (6) to open upwards

↓

③The oil in the throttle groove of the piston (3) starts to flow a little

↓

④The pressure difference between the upper and lower piston (3) due to the throttling action of the throttle groove

↓

⑤The main valve (2) opens upwards against the force of the spring (4) due to the pressure difference.

↓

⑥ A large amount of high-pressure oil can be drained back to the fuel tank, and the pressure of the main oil circuit drops

↓

⑦Protected the oil cylinder and tubing

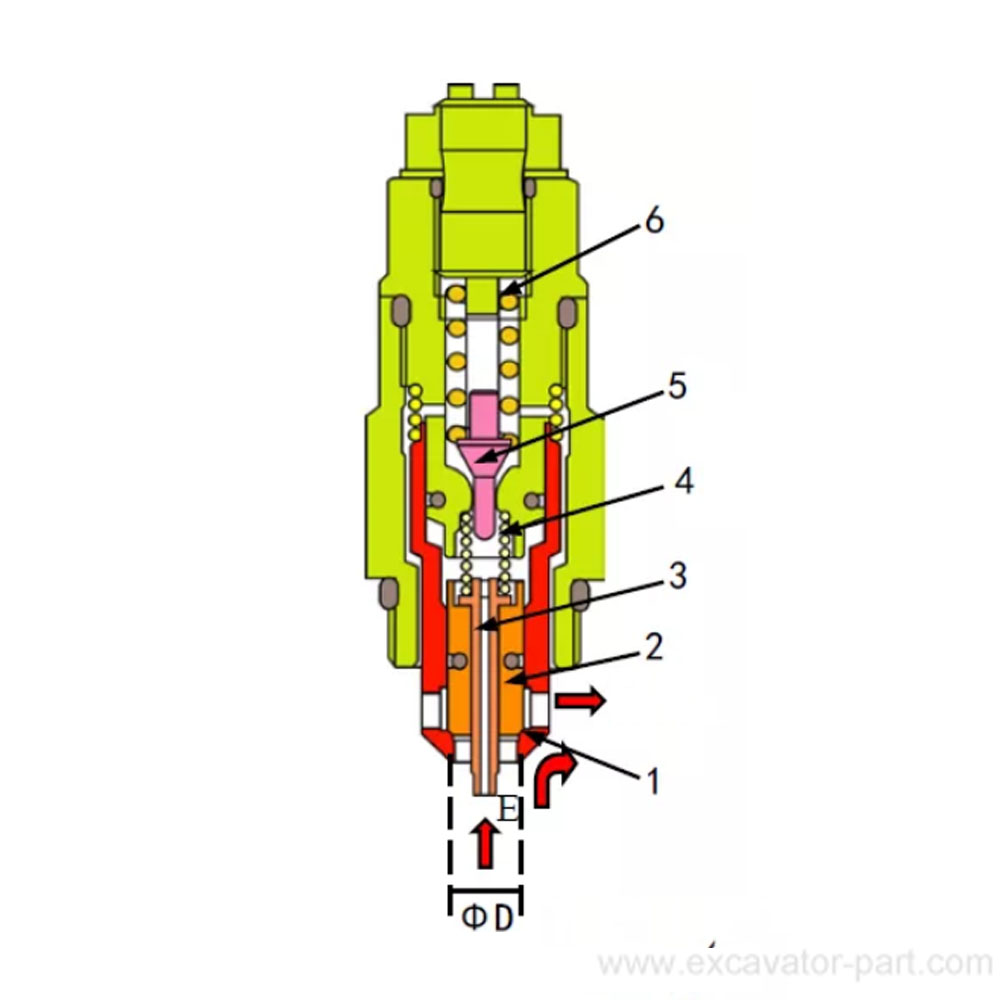

Oil absorption:

①When the E zone is under negative pressure, the oil pressure is lower than the oil tank pressure

↓

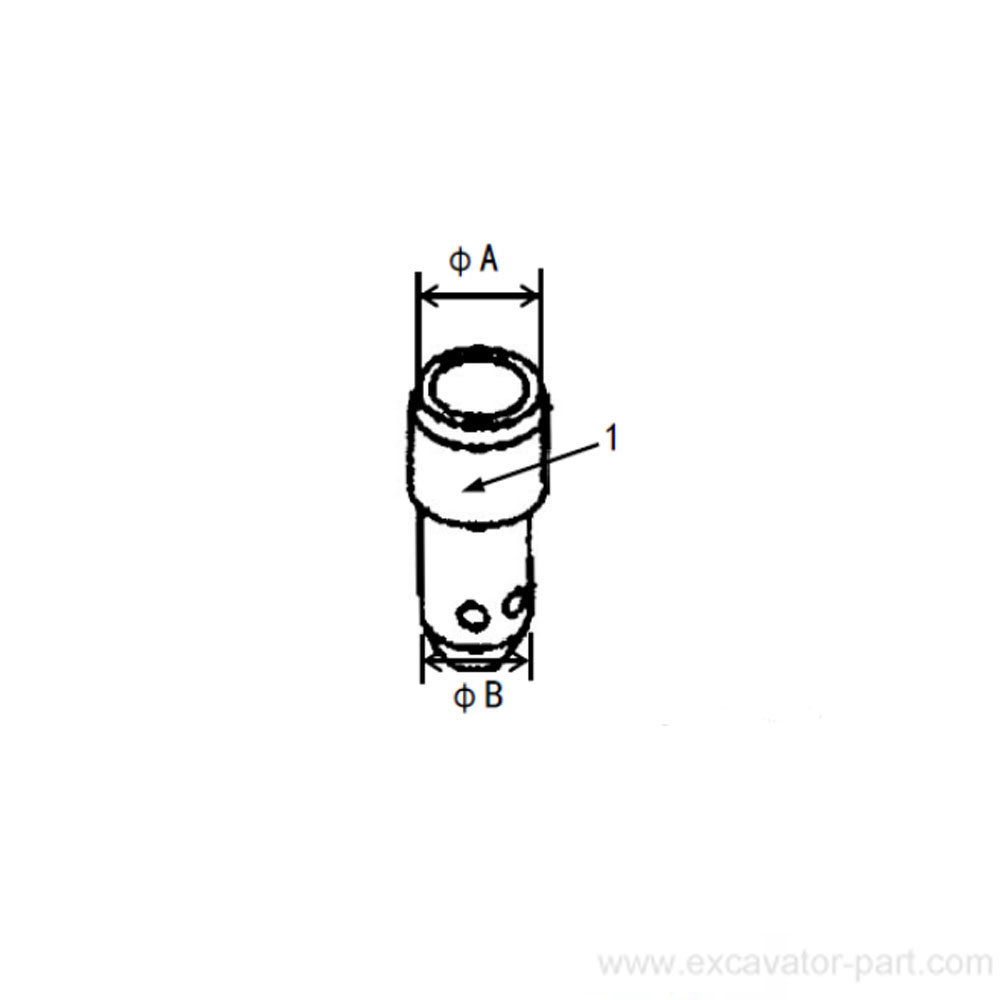

②The oil pressure of the fuel tank acts on the circular force surface of ΦA-ΦD, pushing the suction valve (1) upward to open

↓

③The fuel tank oil fills this negative pressure area to avoid the formation of air bubbles and cavitation.

IV.Fault diagnosis

Fault 1 (see Figure 1 on the next page)

Trouble phenomenon: Boom cylinder is bulged after being impacted by high pressure.

Inspection result: the main valve (2) of the safety suction valve at the bottom of the boom cylinder is stuck and cannot be moved.

Failure analysis: When the abnormal high pressure reaches 390kg/cm2 or more, the main valve (2) cannot be opened yet

Open, causing continuous abnormal high pressure, and the cylinder barrel is deformed by huge internal force.

Troubleshooting: After decomposition, it is found that the main valve (2) is seriously damaged (there are two deep scratches).

It cannot be repaired, so replace the safety suction valve. After disassembling the boom cylinder

The bulge was serious and could not be repaired, so the boom cylinder shell was replaced.

Fault 2 (such as running deviation problem)

Trouble phenomenon: The boom is obviously lowered naturally.

Inspection result: There are obvious scratches on the cone surface of the poppet valve (5).

Failure analysis: due to obvious scratches on the cone of the poppet valve (5), the bottom of the boom cylinder is pressed

Power oil leaks back to the oil tank through the cone surface of the cone valve (5).

Troubleshooting: Replace the boom safety valve and the machine returns to normal.